5 Essential Tips for Effective Purchase Order Management

1. Streamline Purchase Order Creation and Tracking

Efficiently managing purchase orders (POs) is crucial for a smooth procurement process. Here are actionable strategies to streamline PO creation and tracking:

Automate PO Creation

Manual PO creation can be time-consuming and prone to errors.

How to:

- Software Tools: Purchase order software implements an automated system that generates POs based on predefined rules and triggers.

- Integration: Integrate your procurement software with inventory management and accounting systems for seamless data flow.

- Customization: Configure the system to include essential details such as item codes, quantities, and delivery dates.

Centralize Information

Scattered data leads to confusion and delays.

How to:

- Database: Maintain a centralized database or cloud-based repository for all PO-related information.

- Vendor Details: Include vendor names, contact information, and preferred communication channels.

- Item Descriptions: Store detailed descriptions, specifications, and any special instructions.

- Delivery Schedules: Track expected delivery dates and lead times.

Standardized Formats

Consistent formats enhance clarity and reduce misunderstandings.

How to:

- Template Design: Create standardized PO templates with clearly defined sections.

- Fields to Include:

- Header: Company name, address, and PO number.

- Vendor Details: Vendor name, address, and contact information.

- Item Details: Description, quantity, unit price, and total amount.

- Delivery Instructions: Shipping address, delivery date, and any special requirements.

- Terms and Conditions: Payment terms, return policies, and warranties.

- Approval Workflow: Establish a clear approval process for POs.

2. Organize Your Item Catalog

A well-organized item catalog is essential for efficient purchasing. Follow these steps to enhance your catalog management:

1. Categorize Items Logically

Logical grouping simplifies searching and selection.

How to:

- By Category: Arrange items based on product categories (e.g., electronics, office supplies, raw materials).

- By Department: Group items relevant to specific departments (e.g., marketing, operations, IT).

- By Supplier: Create sections for each supplier's products.

2. Regularly Update the Catalog

Accurate and up-to-date information prevents errors and ensures informed purchasing decisions.

How to:

- Product Descriptions: Provide detailed and clear descriptions for each item.

- Pricing: Keep prices current and adjust as needed.

- Availability: Mark items as in stock, out of stock, or back-ordered.

- Images: Include product images for visual reference.

3. Design a User-Friendly Interface

An intuitive interface improves user experience.

How to:

- Search Functionality: Implement a robust search feature that allows users to find items quickly.

- Filters and Sorting: Enable users to filter by category, price range, or other relevant criteria.

- Clear Layout: Organize the catalog with a clean design, consistent fonts, and easy-to-read labels.

- Mobile Compatibility: Ensure the catalog works well on mobile devices.

3. Strengthen Supplier Relationships

Effective supplier management is a cornerstone of successful procurement. By nurturing strong relationships with your suppliers, you can enhance collaboration, mitigate risks, and drive better outcomes. Here are key practices to strengthen those crucial bonds:

1. Vendor Evaluation

Regular assessment ensures you're working with reliable partners.

How to:

- Performance Metrics: Define key performance indicators (KPIs) specific to each supplier. Evaluate factors such as on-time delivery, quality, and responsiveness.

- Scorecards: Create supplier scorecards to track performance over time.

- Feedback Loop: Provide constructive feedback to suppliers based on their performance.

2. Negotiate Favorable Terms

Favorable terms benefit both parties and contribute to long-term collaboration.

How to:

- Payment Schedules: Discuss payment terms that align with your cash flow and the supplier's needs.

- Discounts: Explore volume-based discounts or early payment incentives.

- Delivery Timelines: Set clear expectations for lead times and delivery schedules.

3. Collaborate Actively

Active collaboration drives innovation and efficiency.

How to:

- Joint Initiatives: Engage in joint projects or initiatives with suppliers. Seek their expertise for process improvements or product enhancements.

- Regular Meetings: Schedule regular meetings to discuss challenges, opportunities, and strategic alignment.

- Transparency: Share relevant information about your business goals and supply chain requirements.

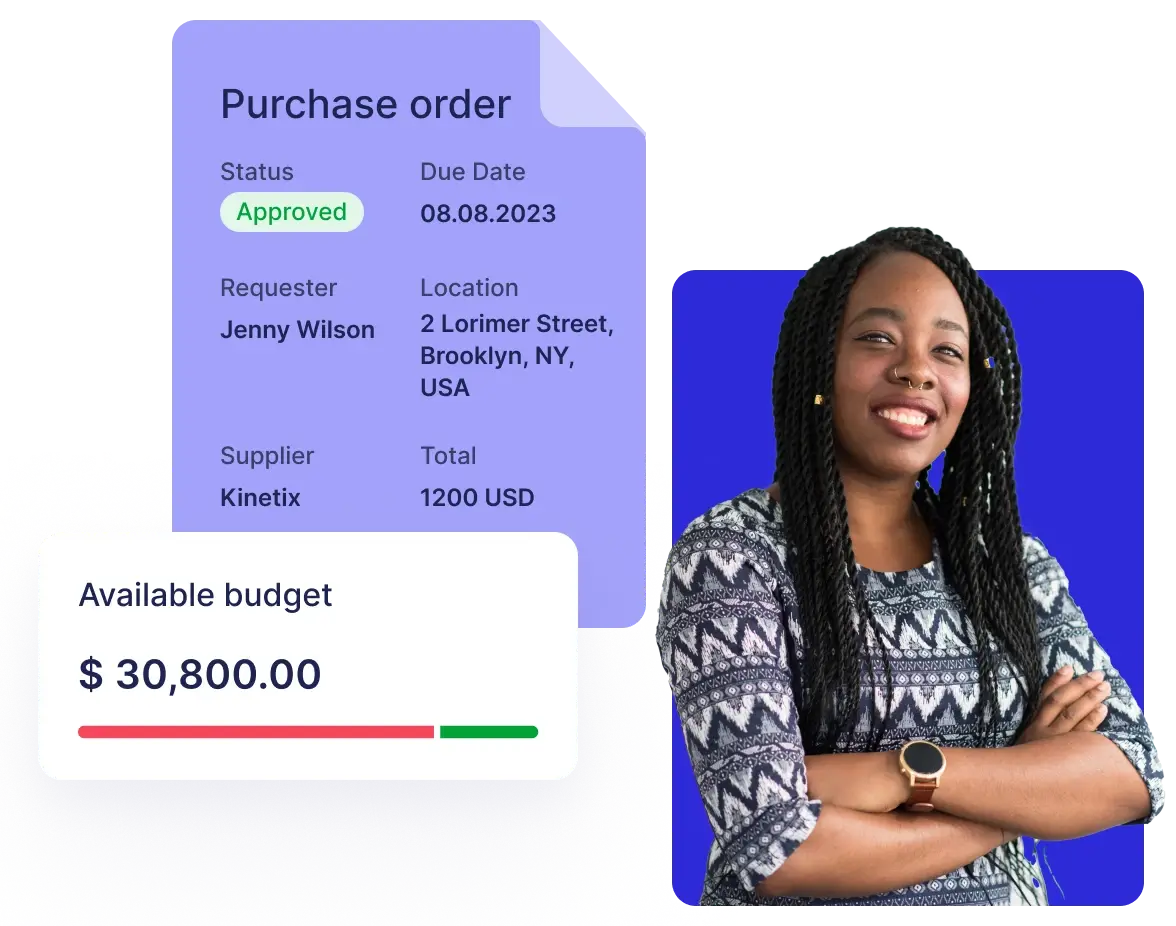

4. Monitoring Purchase Order Progress

Visibility into the purchase order (PO) lifecycle is essential to ensure timely deliveries and minimize disruptions.Effective purchase order management within a supply chain often extends to the timing and methods of transporting purchased goods. For businesses requiring specialized logistics, such as shipping a box truck, ensuring that procurement cycles align with transportation can greatly reduce inefficiencies. Here are actionable steps to effectively monitor PO progress:

1. Real-Time Monitoring

Real-time tracking allows you to stay informed about the status of each PO.

How to:

- Software Tools: Utilize specialized procurement or supply chain management software to track POs from creation to fulfillment.

- Dashboard Views: Access a centralized dashboard that displays the current status of all active POs.

- Updates: Regularly review updates on order processing, shipment, and delivery.

Implementing advanced logistics solutions can further enhance the efficiency and accuracy of PO monitoring, providing a comprehensive approach to supply chain management.

2. Set Up Alerts

Alerts keep you informed about critical milestones and potential issues.

How to:

- Automated Notifications: Configure alerts for specific events, such as order approval, shipment dispatch, and goods receipt.

- Threshold Alerts: Set thresholds for delivery delays or discrepancies. Receive alerts when these thresholds are exceeded.

- Escalation Paths: Define escalation paths for urgent situations (e.g., delayed shipments).

3. Prompt Issue Resolution

Addressing discrepancies promptly prevents supply chain disruptions.

How to:

- Discrepancy Reports: Regularly review reports that highlight discrepancies between the original PO and actual deliveries.

- Collaborate with Stakeholders: Involve relevant teams (e.g., procurement, logistics, finance) to resolve issues efficiently.

- Root Cause Analysis: Investigate the reasons behind delays or discrepancies and take corrective actions.

Remember, proactive monitoring ensures that POs progress smoothly, orders are fulfilled on time, and potential disruptions are mitigated.

5. Leverage Technology for Accuracy

Advanced technologies play a crucial role in enhancing the accuracy and efficiency of purchase order management. Here are key technological approaches to consider:

1. Optical Character Recognition (OCR)

Manual data entry from paper-based documents is time-consuming and error-prone.

How to:

- Automated Extraction: Implement OCR software to scan and extract relevant information (such as vendor names, item codes, quantities, and prices) from printed or handwritten documents.

- Data Validation: Validate the extracted data against predefined formats or rules.

- Integration: Integrate OCR with your procurement system for seamless data transfer.

2. 2-Way and 3-Way Matching

Ensuring consistency between the PO, goods receipt, and invoice is critical for accurate financial records.

How

to:

- 2-Way Matching:

- Compare the PO with the receipt of the goods (received items).

- Verify that quantities and item descriptions match.

- Resolve discrepancies promptly.

- 3-Way Matching:

- Add the invoice to the comparison process.

- Ensure that the invoice aligns with both the PO and goods receipt.

- Validate pricing and other terms.

3. Budget Management

Overspending can impact financial stability. Using spend management software can provide real-time insights and control over expenditures, ensuring financial stability while optimizing budget allocation.

How to:

- Allocate Budgets: Set budget limits for specific categories, departments, or projects.

- Monitor Spending: Regularly track actual spending against allocated budgets.

- Alerts: Receive alerts when approaching or exceeding budget thresholds.

- Adjustments: Adjust budgets as needed based on business priorities.

By embracing these technological tools, your organization can improve accuracy, reduce manual effort, and enhance purchase order management.

Conclusion

In summary, effective procurement management is important for every organization, and an improvable purchase order process lessens the burden of procurement management. The strategic PO creation and management can be made easier by eliminating task duplication, growing the item catalogs, tighter cooperation with suppliers, tracking PO's progress, and implementing of technology for accuracy. This approach will improve efficiency, lessen risks, and contribute to better outcomes during the procurement process.

Functional purchase order management not only enhances operation efficiency but reduces cost and improves supplier association which results in overall business expansion. Applying the best practices and using innovative technology will allow the organizations to simplify as well as speed up the procurement processes, reduce costs and errors, and thus ensure that they will be able to buy goods and services at the given time and amounts.

In the current fast-paced and competitive business environment, having the capability to efficiently streamline purchase orders is a strategy that places businesses ahead of the pack and they are better positioned to be responsive, agile, and competitive. In that regard, this is an essential aspect that needs to be looked into to enhance order process efficiency for the good of business and the long-term benefits.