How AI is Revolutionizing PCB Manufacturing Processes

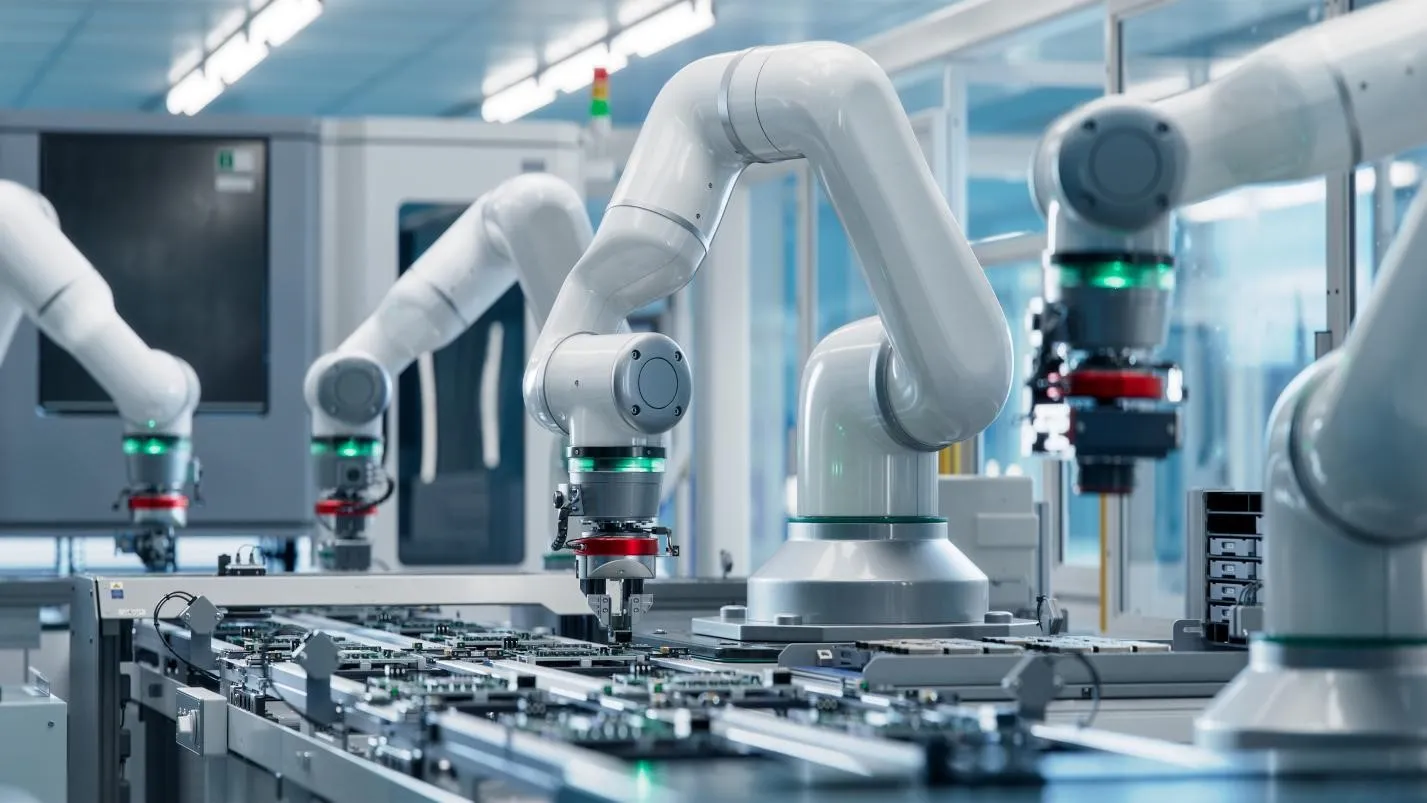

High-precision robotic arms in an electronics factory

AI is part and parcel of Industry 4.0, a term that is synonymous with smart manufacturing. In PCB manufacturing, AI is playing a significant role in achieving Industry 4.0 by introducing machine learning, deep learning, robotics, and automation to streamline PCB design and manufacturing.

This technology is important because PCB fabrication is becoming increasingly complex as electronics miniaturize and customers need faster times to market. So, let’s look at how AI is revolutionizing PCB manufacturing processes to enable quick, low-cost, and high-quality production.

How AI is Revolutionizing PCB Design

For most people, PCB design is separate from manufacturing, which is true. But these two stages in printed circuit board production are heavily intertwined, so let’s start from here.

Speeding Up PCB Design

AI excels in prediction, and this is critical in PCB design because AI algorithms can predict potential issues that might affect board performance early on during design to enable designers to rectify them before prototyping. Such issues include thermal hotspots and poor signal transmission (integrity). Besides speeding up the design process, this error prediction capability increases the reliability and accuracy of the final PCB.

The automated design also incorporates PCB layouts, where sufficiently trained AI algorithms can optimize these files to enhance the manufacturability of the circuit board. But these algorithms must be able to analyze vast amounts of data to optimize the layouts, which include:

- Manufacturing constraints

- Historical design patterns

- Component libraries

Enhancing Design Complexity

As electronics miniaturize, they are becoming more complex to provide more functionality in compact packages. Designing such boards manually can take a long time and have multiple potential errors that can lead to poor performance or failure.

But AI algorithms make it easy to design complex, multilayer, and HDI PCBs by managing tasks like trace routing and component placement while reducing noise, enhancing efficiency, and taking care of factors like impedance matching.

AI tools can also automate or speed up some design tasks by helping to:

Generate scripts or code

- Automate testing

- Select the most suitable or available components

- Summarize datasheets

How AI is Revolutionizing PCB Manufacturing

AI in PCB manufacturing has proven to be a necessity or asset because the technology enables fab houses to do the following.

Predictive and Perspective Maintenance

PCB manufacturing requires various equipment (such as lamination and drilling machines), as well as conveyors to move the boards through the different stages of production. These machines wear out over time, which can result in costly downtimes.

But with sensors (such as in an IoT network) attached to these machines, data can be fed to an AI predictive analytics system to forecast when a machine might break down. For instance, the algorithm can analyze the vibration data coming from sensors attached to a conveyor line to detect if it is within or outside the manufacturer’s recommended limits.

This precise prediction can help to schedule equipment maintenance at the right time when production isn’t too busy. It can also help to prevent costly breakdowns, which might require complete overhauls instead of simple parts replacements. The goal here is to reduce production costs as much as possible, and keeping machines running smoothly at all times ensures PCB production runs at its highest efficiency.

Automate and Optimize Fabrication Processes

The same sensor IoT network can be implemented throughout the entire factory floor to help identify bottlenecks or less efficient operations in real-time. AI analytics can process this data and recommend optimized process parameters to achieve the highest efficiency. Better yet, AI can automate the entire production process, tweaking each parameter in real-time to achieve the best PCB quality and production efficiency.

Fab houses are also adopting AI AGV robots to increase employee outputs or automate some production steps, such as component placement (in PCB assembly), because they are faster, more precise, and run 24/7. Overall, this lowers costs, a benefit that ends up with the customers.

Automate Inspection for Tight Quality Control

One of the most significant applications of AI in PCB manufacturing is automated inspection. Setting up this system requires a golden board, which serves as the reference for the inspection. One or more cameras capture images of the PCBs after production and send them to the AI engine, which compares them to the golden board to spot defects, including minute ones like misaligned vias. This process is faster and more precise than using a human and takes less time to configure than AOI.

A machine vision system inspecting PCBs

Optimize Supply Chain Management for Inventory Control

The PCB supply chain is complex because you need lots of materials and components to make the boards. An AI-powered supply chain management system can streamline this part of production by analyzing the lead times, demand patterns, and inventory levels to forecast demand, make the chain more responsive, and reduce delays.

Wrap Up

AI is like an artificial human brain because it possesses intelligence. So, using it in PCB manufacturing is a smart move because it is like introducing an employee who’s always accurate, works without getting tired, and operates quickly. The result is fast, precise, low-cost manufacturing, which leads to low-cost, high-quality electronic products.

Even though the AI adoption process is expensive at first, the cost and time savings achieved later, plus enhanced manufacturing and improved product quality are worth the investment. So, if you’re into PCB production, AI is worth considering in PCB manufacturing.